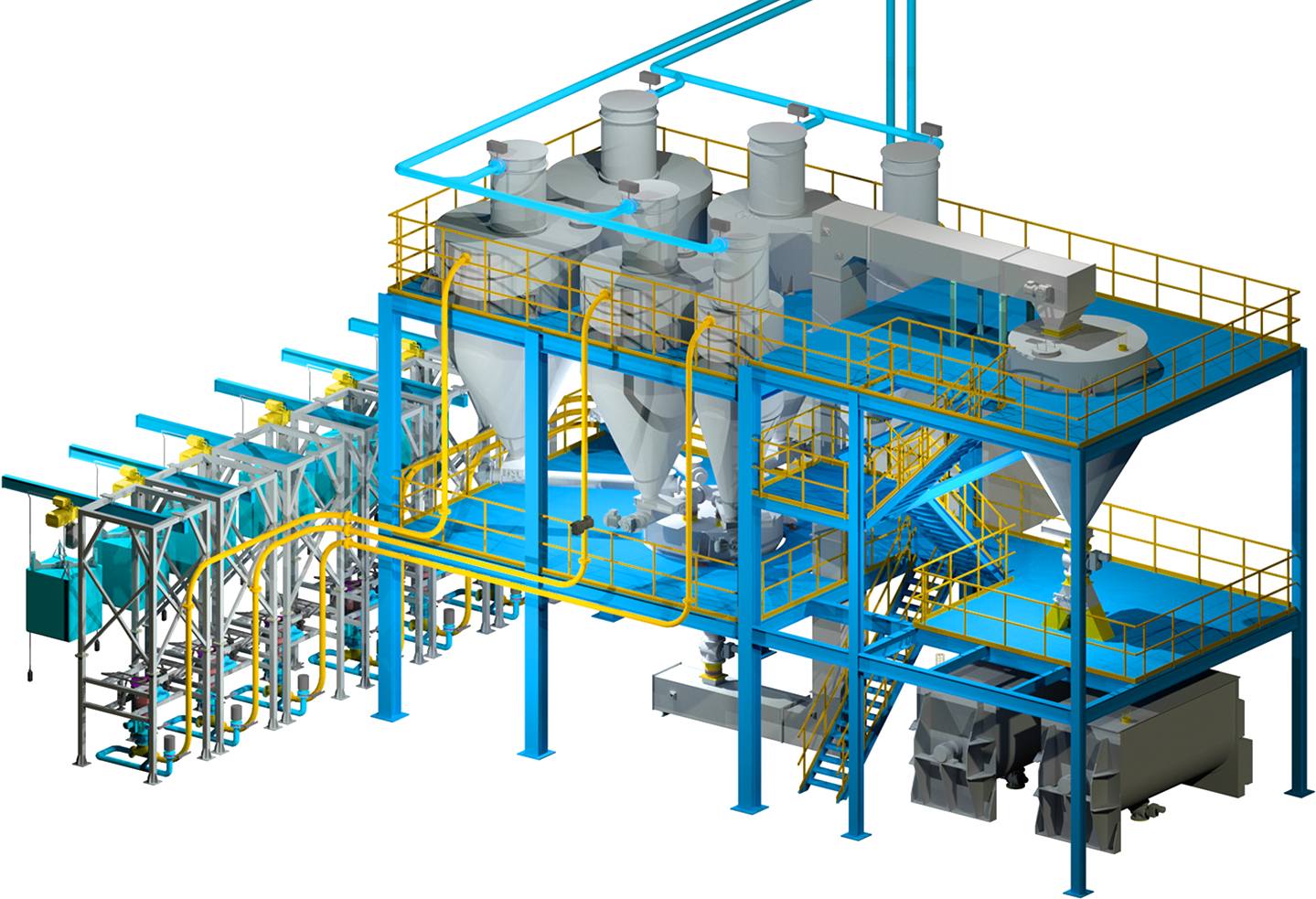

LFP

Ternary cathode

Lithium battery cathode

Lithium battery slurrymixing

Other fine chemical production lines

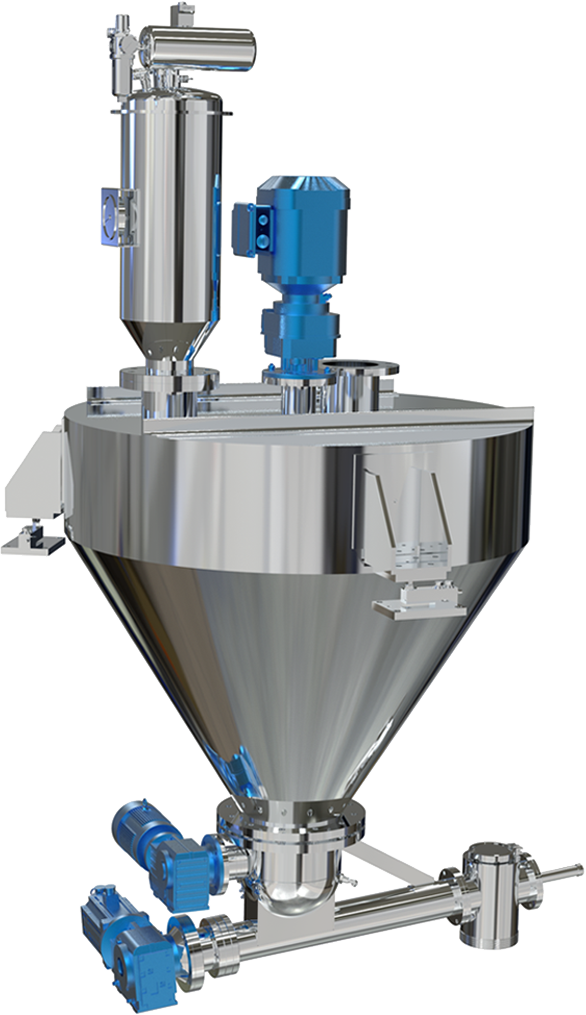

Used for precise ingredient feeding of raw materials, with a gap of 1-2mm between screw blades and pipe wall

The conveying pipeline has minimal residue, and the spiral outlet is equipped with sealing, which can stably control the batching accuracy of ± 1 ‰

Each batch has a processing capacity of 0.1-20 cubic

Meters 0.3-15 tons of processed materials per batchThe

Mixing time used is 3-15 minutesThe equipment material

Can be 316L, 321, 304, or carbon steel

Normal temperature and pressure

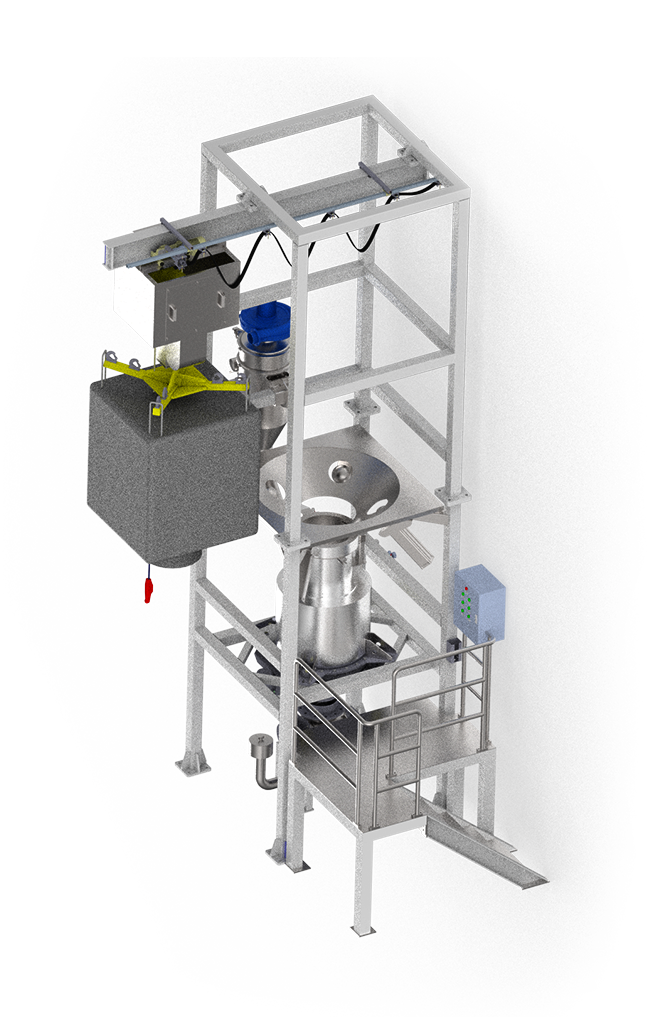

Feeding specification: < 50Kg Feeding method

Manual+vacuum suction cup

Unpacking speed: ≤ 30 bags/h

Dust removal method: pulse back blowing

Equipment power: 1.1-3.3Kw

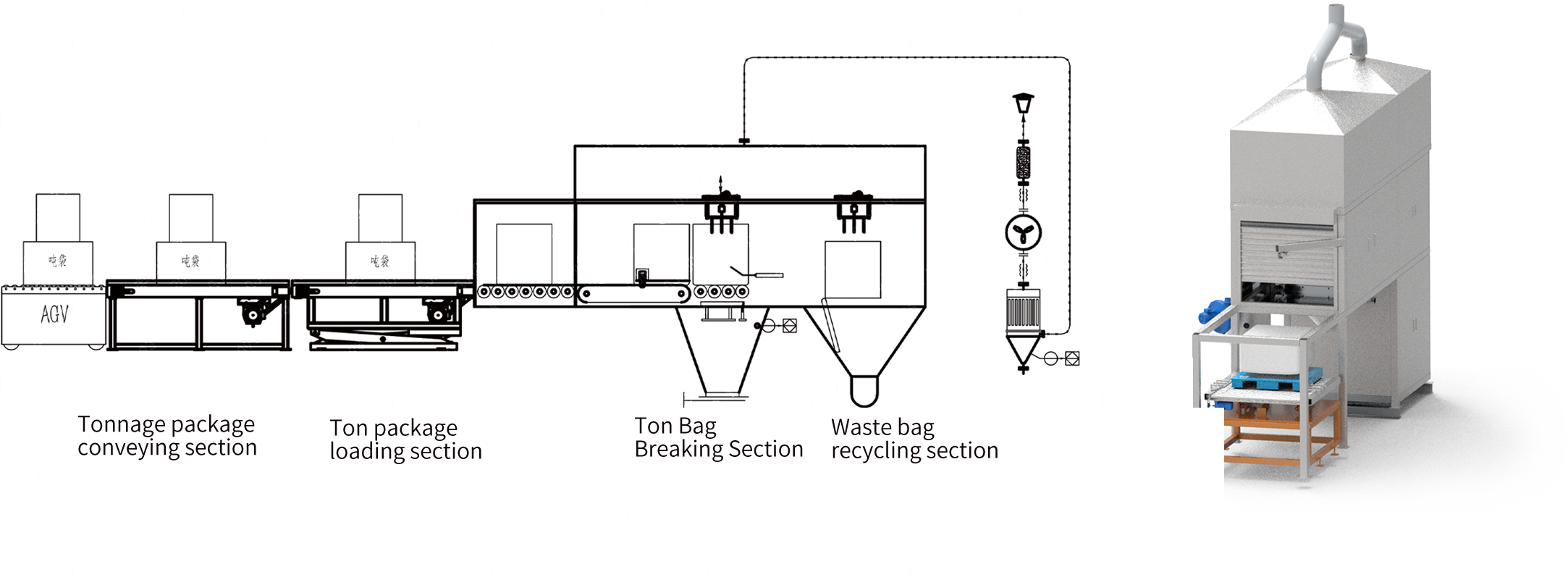

Normal temperature and pressure

Feeding specification: 200-1000Kg

Feeding method: hanging+manual+tapping mechanism

Unpacking speed: ≤ 10 bags/h

Dust removal method: pulse back blowing

Equipment power: 1.1-3.3Kw

The fully automatic ton bag breaking system independently developed by Huacai has a residual feeding rate of less than 1%, and the feeding dust can be recovered, greatly reducing material loss. At the same time, it adopts a sealed form of organ cover, air shower room, and rolling shutter door, which can effectively control environmental dust.