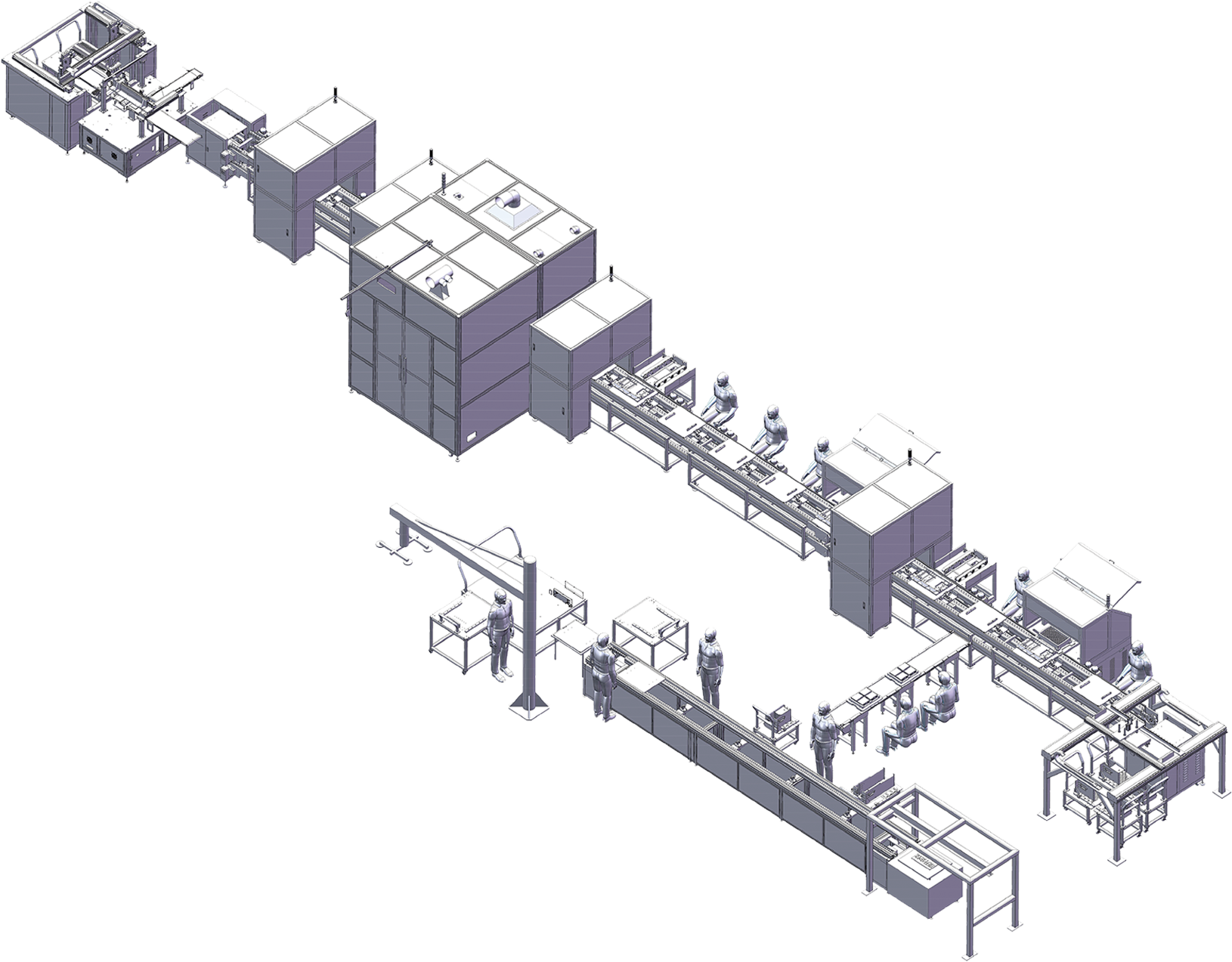

This line is an assembly production line for square module battery packs, which includes processes such as cell loading, cell scanning, OCV testing, plasma cleaning, cell gluing/pasting, cell stacking, end and side plate welding, pole cleaning, pole addressing, BUSBAR welding, post weld cleaning, module entry into the box, box fastening, PACK assembly, PACK testing offline, etc., to complete the assembly production from the module to the PACK pack.

| Size | 86000*6000*6500mm |

| Gas source | 0.5-0.7MPa |

| Source | 380VAC,50Hz |

| Power | 380-500KW |

| Capacity | 15PPM |

Check the voltage and internal resistance of the battery cell to ensure the quality of the module and improve the performance of the module product

Unified stacking benchmark, ensuring module size and position accuracy, and improving module yield

CCD photo positioning technology improves welding accuracy and equipment yield

Using circular spot welding to improve welding quality and reduce welding spatter

Flexible production line, compatible with multiple battery cells and modules, with built-in formula function for one click switching between different formulas