| Equipment model | Equipment size(mm) | Adapt to substrate width(mm) | Baking box(m) | Heating method |

|---|---|---|---|---|

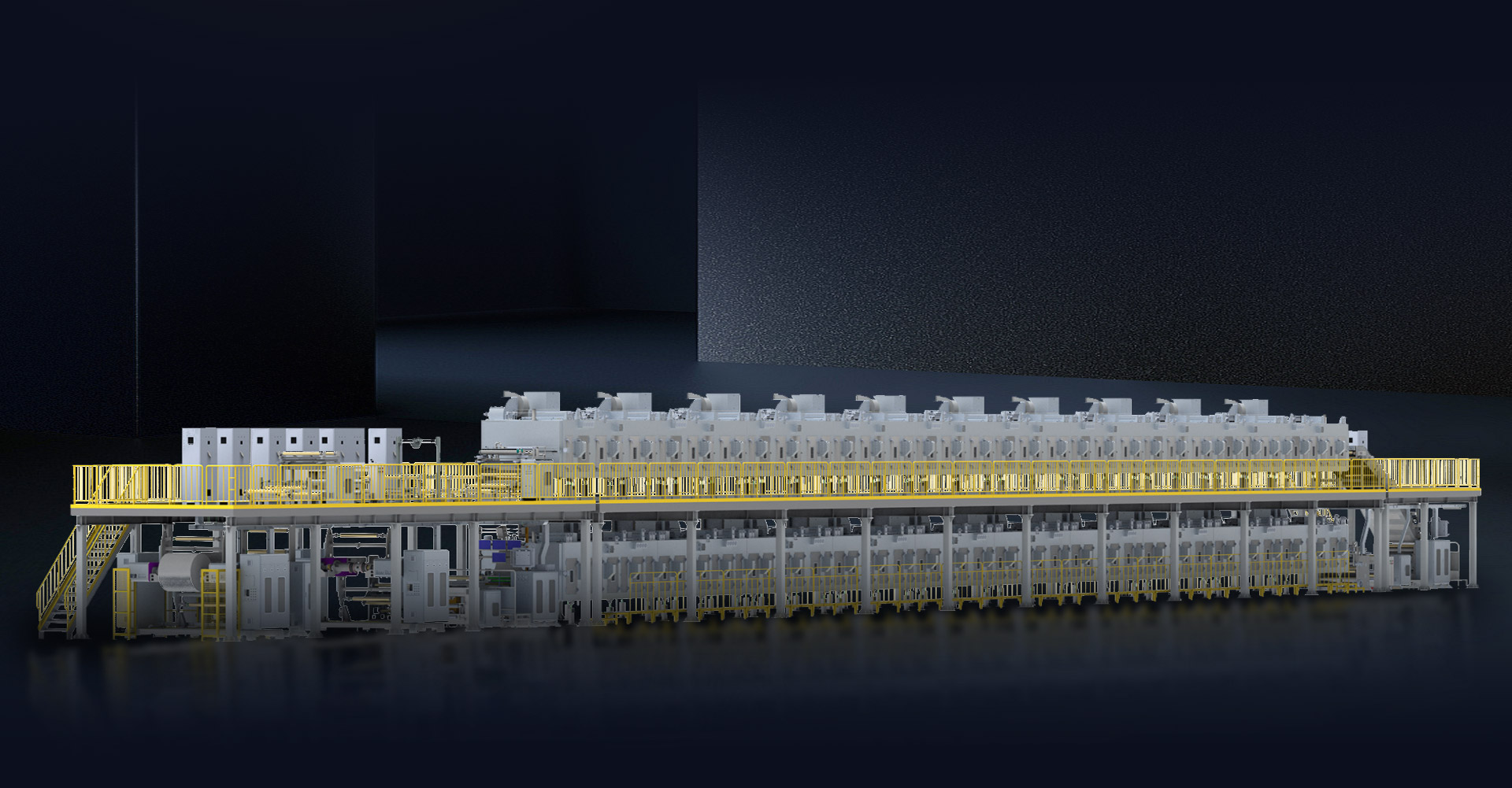

| LSDA-1200-60.60.A.A | 86000*6000*6500 | 1050 | 65 | Steam/thermal oil |

| LSDA-1400-65.65.A.A | 91000*6300*6500 | 1250 | 65 | Steam/thermal oil |

| Product parameters | Parameter values |

|---|---|

| Coating method | Narrow slit continuous extrusion coating |

| Coating width | MAX:1050mm/1250mm |

| Coating speed | MAX:70m/min |

| Coating size accuracy | ≤±0.3mm |

| Coating weight accuracy | ±1% |

| Coating surface density | 5~30mg/cm² |

| Substrate thickness | AL9~20μm/Cu4.5~20μm |

| Roll diameter/weight | MAX:φ1200mm/3000kg |

| Equipment parameters | Parameter values |

|---|---|

| Mechanical speed | MAX:100mm/min |

| Roll surface width | MAX:1200mm/1400mm |

| Speed accuracy | ≤0.05% |

| Coating roller circular runout | ≤1.5um(laser gauge) |

| tension | 30~500N/±2N |

| Oven temperature | MAX:150C/±2C |

The coating machine adopts a "temperature difference" baking method, which is conducive to the drying and forming ofthe electrode and improves the baking quality of the electrode.

In the actual baking and heating process of the coating machine, the larger the actual temperature difference required forthe baking condition, the more energy-efficient the "temperature difference" baking mode is;. The energy-saving effect issignificant in the preheating section and the deceleration drying section of the polarizer baking, followed by theenergy-saving effect in the constant speed drying section, but the effect of preventing polarizer curling is significant.

The precise "temperature difference" diferentiated heating and baking mode from top to bottom reduces the air flow foruseless work and effectively improves the utilization rate of heat energy.